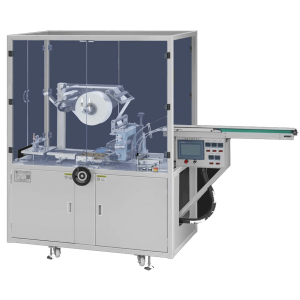

150 Flat blister packaging machine JBL-150-1

1. The traction uses servo motor drive technology (precision screw traction, rubber pressure roller traction), accurate synchronization, and the travel length can be freely set by the human-machine interface.

2. Configure the cursor to match the plate sealing device, making the plate pattern consistent, clear and pleasing to the eye.

3. Set up four workstations – forming, heat sealing, indentation, punching, etc.- all with the same spline central axis positioning, each workstation can move independently, making calibration convenient.

Ask for quoteVideo

Specs

| Punching frequency | 15-35 times/min (hard aluminum, large honey pill 8-20 times/min) |

| Maximum forming area and depth | 140*110*26mm |

| Production capacity | 4200 plates/hour (duraluminum, large honey pills 600-1200 plates/hour) |

| Standard travel range | 20-110mm (Can be designed according to customer requirements) |

| Working air pressure | 0.6-0.8MPa |

| Standard page | 80*57mm (Can be designed according to customer requirements) |

| Total power supply | 380V/220V, 50Hz, 5.2Kw |

| Main electrode power | 1.5Kw |

| PVC hard sheet | 0.15-0.5*140mm |

| PTP aluminum foil | 0.02-0.035*140mm |

| Dialysis paper | 50-100*140mm |

| Comprehensive noise | <75dBA |

| External dimensions | 2300*650*1615mm |

| Total weight | 900kg |

| Packed size | 2360*710*1795mm |

| Volume | 503kg |

Application

Electronic cigarette industry, as well as food industry, daily chemical industry, electronic products industry, cosmetics industry, pharmaceutical industry

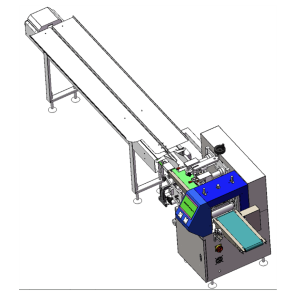

Labeling machine

Labeling machine E-liquid filling machine

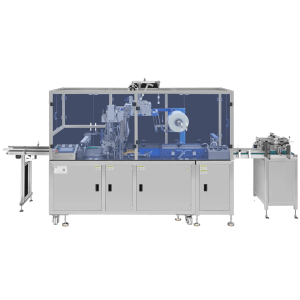

E-liquid filling machine Packaging machine

Packaging machine